The goal of this post and of planning in general is to anticipate possible and plausible future conditions to better help leaders make informed decisions along the way. According to wikipedia.org (accessed 09-23-2014)

The goal of this post and of planning in general is to anticipate possible and plausible future conditions to better help leaders make informed decisions along the way. According to wikipedia.org (accessed 09-23-2014)

“3D printing or additive manufacturing is any of various processes for making a three-dimensional object of almost any shape from a 3D model or other electronic data source primarily through additive processes in which successive layers of material are laid down under computer control. A 3D printer is a type of industrial robot.

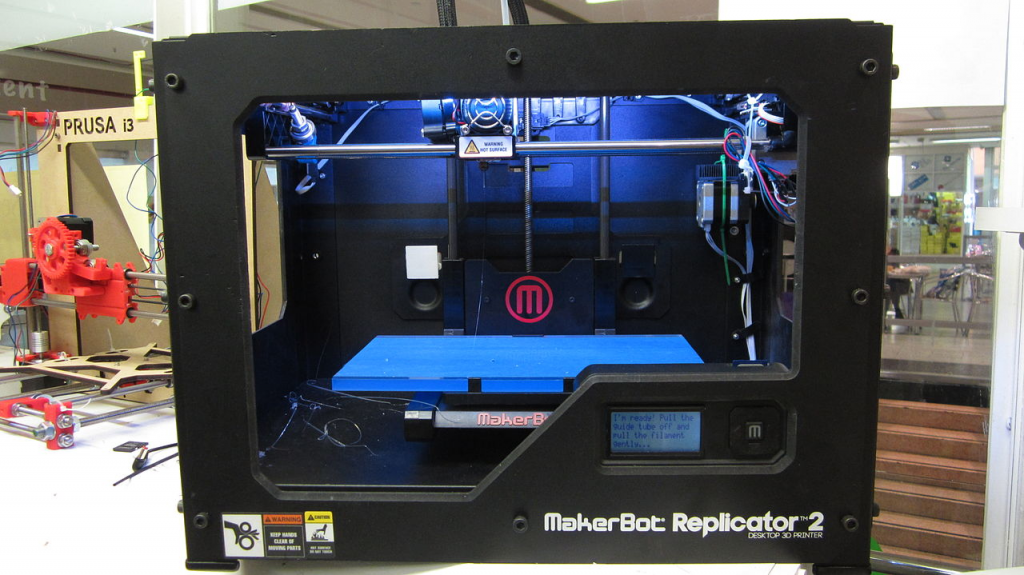

The above image is of a 3D printer that prints using plastic polymers. Advances are being made in the printing of metals and even food grade materials. The advantage of 3D printers is that final printed object contains no scraps or waste. The printer only uses the amount of material necessary for production. This could have wide-ranging implications for the size and scale of manufacturing and how it fits in with urban form and transportation demand. 3D printing’s implications for long-range transportation planning and related decisions by leaders and elected officials revolve around it’s potential to affect both “economies of scale” and “economies of agglomeration.”

Economies of scale are savings that occur to an individual entity (i.e. factory) or process when there are high fixed costs and the price per item manufactured goes down as the volume goes up. Essentially, each additional item manufactured helps repay the high fixed costs, so “the more the merrier!” The classic example is a large factory. Since traditional manufacturing processes can require large volumes to reach economies of scale, manufacturing is typically located away from residential, commercial and retail uses. 3D printing has the potential to alter the volume necessary to reach economies of scale. 3D Printing based manufacturing could potentially be small enough to co-exist with commercial, retail and in some cases residential land uses.

Economies of agglomeration are savings and benefits to a company or organization when it locates close to other businesses and organizations. These savings are usually due to potential productivity gains, savings on input costs (i.e. labor), and knowledge spillovers from the concentration of professionals, entrepreneurs and other creative individuals within a given geographic area. The potential for 3D printing to operate at a small scale may allow it to be located near complementary business and markets thus reducing transportation demand.

Since 3D Printing is in its infancy, the extent to which it alters typical economies of scale and economies of agglomeration of manufacturing and thus manufacturing derived transportation demand remains to be seen. Therefore, as we develop the next long-range transportation plan we would like to ask for your feedback on several questions. Please provide answers in the comment box below.

- Will 3D Printing and other advanced manufacturing technologies dramatically reduce the size and scale needed to reach economies of scale?

- Will small scale 3D printing based manufactures locate in urban and other mixed-use environments?

- Will these impacts account for a significant portion of the manufacturing sector or just niche and custom portions?

- What other questions did we miss/would you suggest?

I’ve been interested in 3-d printing since its inception. But, since 3-d printing works with complex software, a niche market for consumer products seems like a reasonable direction. Except , medical scaffolding of human organs will benefit the most from this technology. It will be very interesting to see how it unfolds.

Please try to use non-toxic filament whenever you can. 3D-Fuel (www.3dfuel.com) has actually come up with an Advanced PLA (APLA)™ filament APLA offers higher tensile strength, improved toughness, ease of printing, and increased performance at higher temperatures than standard PLA or ABS filaments. 3D-Fuel APLA is an improved replacement for commonly used and potentially hazardous petroleum based ABS products. Now, users of APLA can make a sustainable choice without compromising. 3D-Fuel is indeed manufactured and distributed in the United States.

For example, in a 135degC oven, APLA allows extremely little deformability whereas the same size of ABS is easily bent into a U-shape. 3D-Fuel also makes “Algae-Fuel”, algae-infused PLA that doubles the biodegradability of PLA in composts and landfills. Please contact me with any questions.